Seamlessly design around roof obstacles support most framed modules and bond the system with just the turn of a wrench.

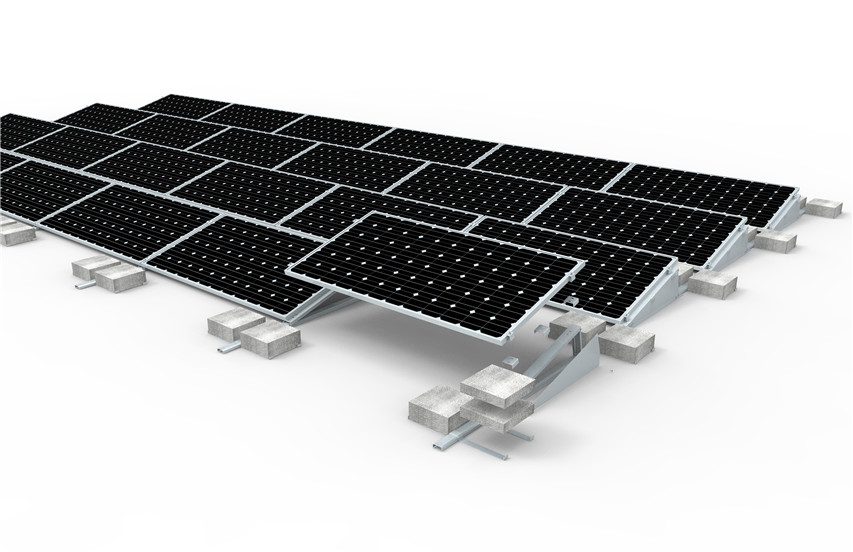

Pad under the solar panels on a ballest system.

With easy assembly and racking system components panels can be easily removed at the customer s request when roof access is required.

The east west system is similar to the south facing system installation however the panels are placed back to back and there is a smaller gap between rows 180mm.

Solar panel installers are presented with a number of challenges when designing and installing flat roof solar panels.

X 8 ft whereas a driven system would only require a single post.

With proper installation a sturdy mount secures your panels in harsh weather and protects your investment.

While this weight can be easily accommodated in new construction existing roofs often do not have the spare capacity to accommodate the additional load.

A ballasted solar system weighs about 5 pounds per square foot increasing on the outside row and at the end of panels as an added measure against wind.

A reputable commercial solar developer will assist their customers throughout the term of the solar service agreement guaranteeing.

Few solar contractors are willing or able to explain that while ballasted systems minimize holes in the roof at first they will result in higher maintenance costs over the life of the system.

Ballasts are most often used in commercial installations where ground penetration is not advised or permitted.

The first reason ballasted racking systems dominate in solar low slope installations is that building owners overwhelmingly dislike poking holes in their roofs to mount a solar racking system.

Yet as we also noted above technology has led to improvements in the way that solar panel arrays are constructed which means that they require less ballast and thus you can build a solar array with.

As we noted above commercial roofs constructed during the 80s and 90s may not be suitable for solar panels using solar ballast because the roof just won t bear the weight of the concrete.

A ballast system uses a man made foundation to hold the rack and panel in place.

Rm10 introduced the power of simplicity to the ballasted flat roof solar industry.

Quick project layout turnaround times solar project layouts completed within 2 3 days of request to support the project planning process.

A further advantage is that the ballast requirements are lower for this system as the structure is more enclosed and there is nowhere for the wind to catch.

A ballasted system usually has two vertical posts connected to a single concrete block approximately 2 ft.

Ecofoot2 s solar panel mounting kits maximize roof capacity and minimize turnaround time through its modular design and optimized engineering process.

Both racking types allow for flexible access to the roof under the panels.

With 10 degree tilt this system consists of only two major components minimizing preparation work and installation time.

Rm10 increase panel output simple design few components.